INOX PNEUMATIC

TECHNICAL DATA

CONSTRUCTION

Endcovers screwed onto Tube for the possiblility to replace Seals

Threads are Loktite secured.

TEMPERATURE

-20 o - 80 o

PRESSURE

1 - 10 Bar

MATERIALS

Endcovers and Pistonrod in AISI 316

Tube in AISI 304 ( Alternative AISI 316 (S))

Piston in POM

Seals in NBR

FUNCTIONS

Double Acting

Single Acting

[ max 80mm Stroke and total lenght increased with 25mm ]

Through Rod

STROKES

ISO Strokes

Stroke > 500 upon request

OPTIONS

FKM/ VITON Seals

Tube in AISI 316

Magnetic Piston

ORDERING CODE EXAMPLE

Type I

Diameter: 40

Function: Doubleacting

Cushion: Adjustable

Stroke: 100

Cushion: Adjustable

Magnetic Piston

Rod Seal/ Wiper In FKM

TYPE

Z

DIAMETER

ø32, 40, 50, 63 80, 100, 125

FUNCTIONS

01: Single Acting Spring Return

02: Single Acting Spring forward

03: Double Acting

04: Through Rod

CUSHION

JB: Adjusable

STROKE [mm]

OPTIONS

M: Magnetic Piston

V: All Seals in Viton/ FKM

Vf: Rod Seal/ Wiper in Viton/ FKM

Pf: Rod Seal/ Wiper in PUR

S: All Parts in AISI 316

Z 040 03 JB 0100 MVf

CYLINDER

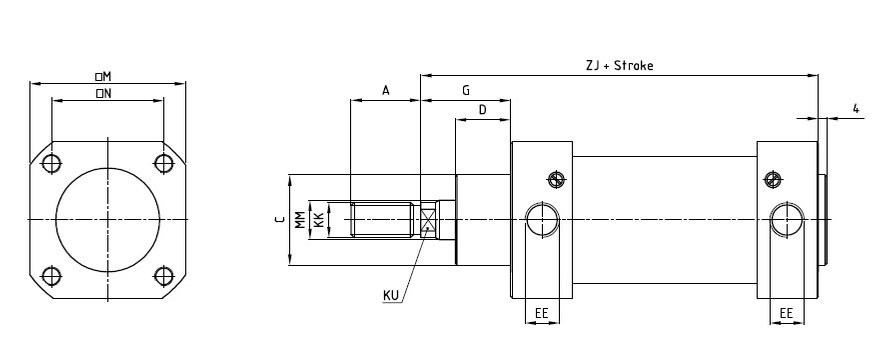

CYLINDER TYPE Z

CYL Ø | M | N | RT | KK | KU | MM | C | A | D | G | EE | ZJ |

32 | 45 | 32.5 | M6 | M10x1.25 | 10 | 12 | 30 | 22 | 16 | 26 | G 1/8" | 120 |

40 | 55 | 38 | M6 | M12x1.25 | 13 | 16 | 35 | 24 | 20 | 30 | G 1/4" | 135 |

50 | 65 | 46.5 | M8 | M16x1.5 | 17 | 20 | 40 | 32 | 25 | 37 | G 1/4" | 143 |

63 | 75 | 56.5 | M8 | M16x1.5 | 17 | 20 | 45 | 32 | 25 | 37 | G 3/8" | 158 |

80 | 95 | 72 | M10 | M20x1.5 | 22 | 25 | 45 | 40 | 33 | 46 | G 3/8" | 174 |

100 | 115 | 89 | M10 | M20x1.5 | 22 | 25 | 55 | 40 | 37 | 51 | G 1/2" | 189 |

125 | 140 | 110 | M12 | M27x2 | 27 | 32 | 60 | 54 | 45 | 65 | G 1/2" | 225 |

BRACKETS

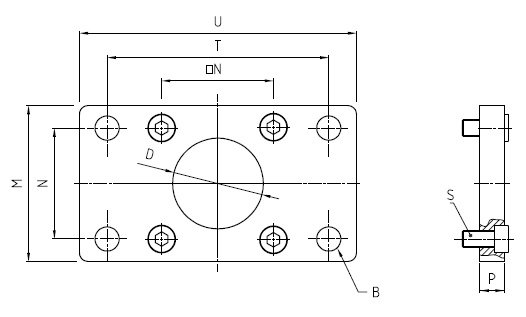

FLANGE

TA

AISI 304

TYPE NO | M | N | L | U | T | D | B |

TA32 | 45 | 33 | 8 | 80 | 64 | 30 | 7 |

TA40 | 55 | 40 | 8 | 90 | 72 | 35 | 9 |

TA50 | 65 | 49 | 10 | 110 | 90 | 40 | 9 |

TA63 | 75 | 59 | 10 | 125 | 100 | 45 | 9 |

TA80 | 95 | 75 | 12 | 154 | 126 | 45 | 12 |

TA100 | 115 | 90 | 12 | 186 | 150 | 55 | 14 |

TA125 | 140 | 110 | 16 | 224 | 180 | 60 | 16 |

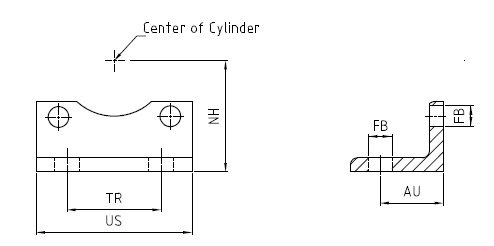

FLANGE FOOT

TB

AISI 304

TYPE NO | US | TR | NH | AU | FB |

TB32 | 48 | 32 | 32 | 24 | 7 |

TB40 | 53 | 36 | 36 | 28 | 9 |

TB50 | 63 | 45 | 45 | 32 | 9 |

TB63 | 75 | 50 | 50 | 32 | 9 |

TB80 | 95 | 63 | 63 | 41 | 12 |

TB100 | 115 | 75 | 75 | 41 | 14 |

TB125 | 140 | 90 | 90 | 45 | 16 |

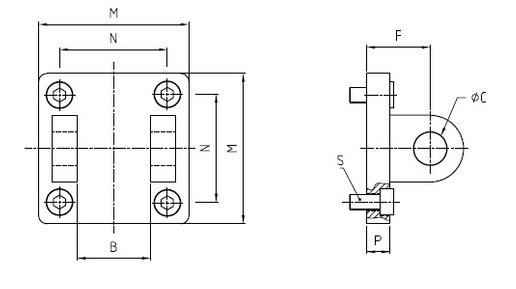

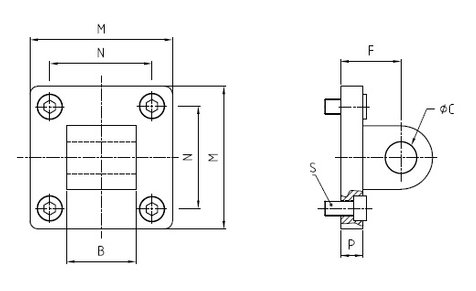

HINGE FEMALE

TC

AISI 304

TYPE NO | M | N | P | B | F | C |

TC32 | 45 | 32.5 | 8 | 26 | 22 | 10 |

TC40 | 55 | 38 | 8 | 28 | 25 | 12 |

TC50 | 65 | 46.5 | 10 | 32 | 27 | 12 |

TC63 | 75 | 56.5 | 10 | 40 | 32 | 16 |

TC80 | 95 | 75 | 12 | 50 | 36 | 16 |

TC100 | 115 | 95 | 12 | 60 | 41 | 20 |

TC125 | 140 | 115 | 16 | 70 | 50 | 25 |

HINGE MALE

TG

AISI 304

TYPE NO | M | N | P | B | F | C |

TG32 | 45 | 32.5 | 8 | 26 | 22 | 10 |

TG40 | 55 | 38 | 8 | 28 | 25 | 12 |

TG50 | 65 | 46.5 | 10 | 32 | 27 | 12 |

TG63 | 75 | 56.5 | 10 | 40 | 32 | 16 |

TG80 | 95 | 75 | 12 | 50 | 36 | 16 |

TG100 | 115 | 95 | 12 | 60 | 41 | 20 |

TG125 | 140 | 115 | 16 | 70 | 50 | 25 |

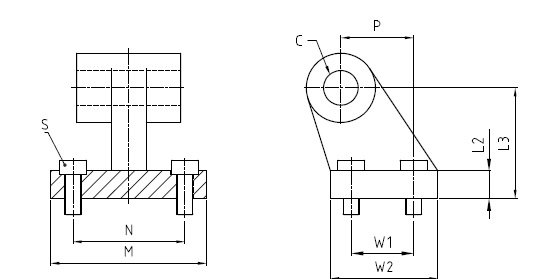

HINGE 90o MALE

AISI 304

TYPE NO | M | N | P | B | L2 | L3 | W1 | W2 | C |

TG32 | 51 | 38 | 21 | 26 | 8 | 32 | 18 | 31 | 10 |

TG40 | 54 | 41 | 24 | 28 | 10 | 36 | 22 | 35 | 12 |

TG50 | 65 | 50 | 33 | 32 | 12 | 45 | 30 | 45 | 12 |

TG63 | 67 | 52 | 37 | 40 | 14 | 50 | 35 | 50 | 16 |

TG80 | 86 | 66 | 47 | 50 | 41 | 63 | 40 | 60 | 16 |

TG100 | 96 | 76 | 55 | 60 | 17 | 71 | 50 | 70 | 20 |

TG125 | 124 | 94 | 70 | 70 | 20 | 90 | 60 | 90 | 25 |